DIN7991 Hex Socket Countersunk Screw Fasalka Kaarboon Steel Zinc Plated Fasalka 8.8 10.9

DIN7991 Hex Socket Countersunk Screw Fasalka Kaarboon Steel Zinc Plated Fasalka 8.8 10.9

Sharaxaada

DEG DEGJawaabta

DEG DEGXigasho

DEG DEGgaarsiin

U DIYAAR GAARINTA MARABKA

10000+ SKU ee bakhaarka

Waxaan u ballan qaadnay alaabta RTS:

70% alaabta la geeyey 5 maalmood gudahood

80% alaabta la geeyey 7 maalmood gudahood

90% alaabta la geeyey10 maalmood gudahood

Dalabka badan, fadlan la xidhiidh adeegga macaamiisha

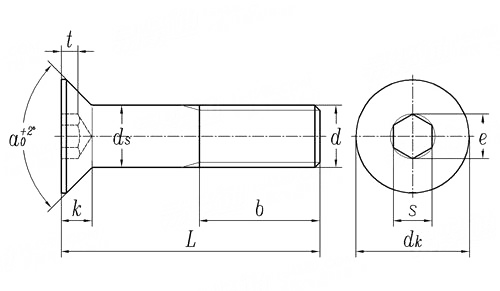

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Garoon | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | tol.(+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125 ML ≤ 200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L >200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Max=Magac ahaan | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Max=Magac ahaan | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Magac ahaan | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Max=Magac ahaan | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

Faahfaahinta

Xidhiidhiyayaasha xoogga sare waxay soo saari doonaan qallafsanaan marka galvanized. Waxay u baahan tahay fiiro gaar ah

Burburinta hydrogen waxaa badanaa lagu gartaa jabka dib u dhaca ee walaaca. Waxaa jiray ilo baabuurta, dhaqida, boolal, ilo xaashida ah iyo qaybo kale oo galvanized ah, dhowr saacadood ka dib markii la jabiyay kulanka, saamiga jabka 40% ~ 50%. Intii lagu guda jiray isticmaalka qaybaha cadmium-ku dahaadhay ee alaabta gaarka ah, waxaa jiray dillaac dildilaac ah, iyo dhibaatada muhiimka ah ee qaranka ayaa la xaliyay waxaana la sameeyay hannaan fuuqbax adag. Intaa waxaa dheer, waxaa jira qaar ka mid ah embrittlement hydrogen ma muujiyaan ifafaale jabka daahday, sida: electroplating hanger (silig birta, silig copper) ay sabab u tahay marar badan oo electroplating iyo pickling, dhexgalka hydrogen waa ka sii halis ah, inta badan u muuqdaan in la isticmaalo laalaabka dhici doona ifafaale jabay; Maandoorkii qoriga, dhowr jeer oo chroming ka dib, ayaa dhulka ku dhacay oo jabay; Qaybaha damay qaarkood ( diiqad weyn oo gudaha ah) ayaa dildillaacaysa marka la gurayo. Qaybahan ayaa si ba'an hydrogenated iyo dildilaac la'aan ah cadaadis dibadda ah, taas oo aan hadda loo isticmaali karin in lagu soo celiyo adkaanta asalka ah by fuuqbaxa.

Mar kasta oo xoogga maaddadu ay sarreyso, waa sii weynaada dareenka embrittlement hydrogen. Tani waa fikrad aasaasi ah oo ay tahay in ay caddeeyaan farsamayaqaannada daaweynta dusha marka la ururinayo qeexida habka korantada. Biraha leh xoogga xajinta σb>105kg/mm2 ee looga baahan yahay heerarka caalamiga ah waa in lagu sameeyaa diiqad ka hor iyo daawaynta fuuqbaxa ka dib. Warshadaha duulista ee Faransiiska waxay u baahan yihiin daawaynta fuuq-baxa u dhiganta ee qaybaha birta ee leh awoodda wax-soo-saarka σs>90kg/mm2.

Sababtoo ah waraaqaha wanaagsan ee u dhexeeya xoogga birta iyo qallafsanaanta, way ka dareen badan tahay oo ku habboon tahay in lagu xukumo dareenka ebrittlement hydrogen ee walxaha by engegnaanta marka loo eego xoogga. Sababtoo ah sawirka alaabta ugu fiican iyo habka mashiinada waa in lagu calaamadeeyaa adagaanta birta. Koronto-samaynta, waxaan ogaanay in adkaanta birta agagaarka HRC38 ay bilowday inay muujiso halista jabka dillaaca hydrogen. Qaybaha ka sarreeya HRC43, fuuqbaxa waa in la tixgeliyaa ka dib marka la dhejiyo. Marka engegnaanta ay ku dhowdahay HRC60, daaweynta fuuq-baxa waa in la sameeyaa isla markiiba ka dib daaweynta dusha sare, haddii kale qaybaha birta ayaa dillaaci doona dhowr saacadood gudahood.

Baakad

nagu saabsan

* Jaantuska soo socdaa wuxuu tilmaamayaa is-dhaafsiga ganacsi ee kala duwan. Fadlan door midka aad doorbidayso.

ALAAB IIBKA KULUL

Tayada Marka hore, Badbaadada waa la damaanad qaaday