DIN912 H59 H62 Brass Hex Socket Cup madaxa furaha

DIN912 H59 H62 Brass Hex Socket Cup madaxa furaha

Sharaxaada

DEG DEGJawaabta

DEG DEGXigasho

DEG DEGgaarsiin

U DIYAAR GAARINTA MARABKA

10000+ SKU ee bakhaarka

Waxaan u ballan qaadnay alaabta RTS:

70% alaabta la geeyey 5 maalmood gudahood

80% alaabta la geeyey 7 maalmood gudahood

90% alaabta la geeyey10 maalmood gudahood

Dalabka badan, fadlan la xidhiidh adeegga macaamiisha

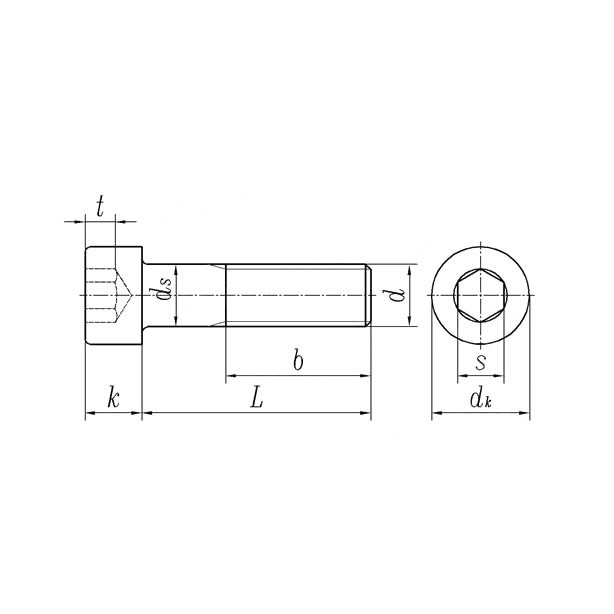

| d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | |

| P | dun aan fiicneyn | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 |

| Dul wanaagsan | / | / | / | / | / | / | / | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 2 | 2 | |

| Dul aad u Fiican | / | / | / | / | / | / | / | / | / | 1 | 1.25 | / | / | 1.5 | 1.5 | |

| b | Qiimaha tixraaca | 14 | 15 | 16 | 17 | 18 | 20 | 22 | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 |

| dk | ugu badnaan (Dhalaan) | 2.6 | 3 | 3.8 | 4.5 | 5.5 | 7 | 8.5 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 |

| ugu badnaan (Knurl*) | 2.74 | 3.14 | 3.98 | 4.68 | 5.68 | 7.22 | 8.72 | 10.22 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 27.33 | 30.33 | |

| Min | 2.46 | 2.86 | 3.62 | 4.32 | 5.32 | 6.78 | 8.28 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | |

| ds | Max | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | |

| k | Max | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.7 | 7.64 | 9.64 | 11.57 | 13.57 | 15.57 | 17.57 | 19.48 | |

| s | Magac ahaan | 1.3 | 1.5 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 14 | 17 |

| Min | 1.32 | 1.52 | 1.52 | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 | 14.032 | 14.032 | 17.05 | |

| Max | 1.36 | 1.56 | 1.56 | 2.06 | 2.58 | 3.08 | 4.095 | 5.14 | 6.14 | 8.175 | 10.175 | 12.212 | 14.212 | 14.212 | 17.23 | |

| t | Min | 0.6 | 0.7 | 1 | 1.1 | 1.3 | 2 | 2.5 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Dhererka xadhigga = b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| d | (M22) | M24 | (M27) | M30 | (M33) | M36 | M42 | M48 | M56 | M64 | M72 | M80 | M90 | M100 | |

| P | dun aan fiicneyn | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6 | 6 | 6 | 6 |

| Dul wanaagsan | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Dul aad u Fiican | 1.5 | / | / | / | / | / | / | / | / | / | / | / | / | / | |

| b | Qiimaha tixraaca | 56 | 60 | 66 | 72 | 78 | 84 | 96 | 108 | 124 | 140 | 156 | 172 | 192 | 212 |

| dk | ugu badnaan (Dhalaan) | 33 | 36 | 40 | 45 | 50 | 54 | 63 | 72 | 84 | 96 | 108 | 120 | 135 | 150 |

| ugu badnaan (Knurl*) | 33.39 | 36.39 | 40.39 | 45.39 | 50.39 | 54.46 | 63.46 | 72.46 | 84.54 | 96.54 | 108.54 | 120.54 | 135.63 | 150.63 | |

| Min | 32.61 | 35.61 | 39.61 | 44.61 | 49.61 | 53.54 | 62.54 | 71.54 | 83.46 | 95.46 | 107.46 | 119.46 | 134.37 | 149.37 | |

| ds | Max | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 |

| Min | 21.67 | 23.67 | 26.67 | 29.67 | 32.61 | 35.61 | 41.61 | 47.61 | 55.54 | 63.54 | 71.54 | 79.54 | 89.46 | 99.46 | |

| k | Max | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 |

| Min | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 41.38 | 47.38 | 56.26 | 63.26 | 71.26 | 79.26 | 89.13 | 99.13 | |

| s | Magac ahaan | 17 | 19 | 19 | 22 | 24 | 27 | 32 | 36 | 41 | 46 | 55 | 65 | 75 | 85 |

| Min | 17.05 | 19.065 | 19.065 | 22.065 | 24.065 | 27.065 | 32.08 | 36.08 | 41.08 | 46.08 | 55.1 | 65.1 | 75.1 | 85.12 | |

| Max | 17.23 | 19.275 | 19.275 | 22.275 | 24.275 | 27.275 | 32.33 | 36.33 | 41.33 | 46.33 | 55.4 | 65.4 | 75.4 | 85.47 | |

| t | Min | 11 | 12 | 13.5 | 15.5 | 18 | 19 | 24 | 28 | 34 | 38 | 43 | 48 | 54 | 60 |

| Dhererka xadhigga = b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

Sawir faahfaahsan

Waa maxay faraqa u dhexeeya Copper, Brass, Bronze?

Copper, Brass iyo Bronze, haddii kale loo yaqaan "Biraha Cas", waxay u ekaan karaan isku mid marka hore. Laakiin runtii waxay leeyihiin farqi badan oo ah curiyaha, waxqabadka iyo wixii la mid ah.

Copper

Copper waxaa loo isticmaalaa noocyo kala duwan oo badeecooyin ah oo ay ugu wacan tahay korantada wanaagsan iyo kuleylka kuleylka, xoogga wanaagsan, qaabaynta wanaagsan iyo iska caabinta daxalka. Tuubooyinka iyo tuubooyinka ku rakiban ayaa caadi ahaan laga soo saaraa birahan sababtoo ah iska caabbinta daxalka. Si diyaar ah ayaa loo iibin karaa oo loo qurxin karaa, qaar badanna waxaa lagu alxan karaa gaas kala duwan, arc iyo habab iska caabin ah. Waa la turxaan bixin karaa oo la qurxin karaa ku dhawaad wax kasta oo la doonayo iyo dhalaalid.

Waxaa jira darajooyin naxaas ah oo aan daawaynta lahayn, waxayna ku kala duwanaan karaan xadiga wasakhda ah ee ku jirta. Darajooyinka naxaasta ah ee aan ogsijiinta lahayn ayaa si gaar ah loogu isticmaalaa shaqooyinka meelaha tamarta sare iyo ductility looga baahan yahay.

Mid ka mid ah sifooyinka ugu muhiimsan ee naxaasta ayaa ah awoodda ay ula dagaallanto bakteeriyada. Ka dib baaritaan dheer oo ka hortag ah oo ay samaysay Hay'adda Ilaalinta Deegaanka, waxaa la ogaaday in 355 alloys oo naxaas ah, oo ay ku jiraan naxaasyo badan, la ogaaday inay dishay in ka badan 99.9% bakteeriyada laba saacadood gudahooda. Wasakhaynta caadiga ah ayaa la ogaaday inaysan wax u dhimayn waxtarka ka hortagga jeermiska.

Codsiyada Copper

Copper wuxuu ahaa mid ka mid ah biraha ugu horreeya ee la helay. Giriigta iyo Roomaanku waxay ka dhigeen qalab ama qurxiyo, xitaa waxaa jira faahfaahin taariikhi ah oo muujinaysa codsiga naxaasta si loo nadiifiyo nabarrada loona nadiifiyo biyaha la cabbo. Maanta waxaa inta badan laga helaa qalabka korantada sida fiilooyinka sababtoo ah awoodda ay u leedahay inay si wax ku ool ah u qabato koronto.

Naxaas

Naxaasta inta badan waa alloy ka kooban naxaas oo zinc lagu daray. Naxaasyadu waxay yeelan karaan xaddi kala duwan oo zinc ah ama walxo kale oo lagu daray. Isku dhafkan kala duwan ayaa soo saara noocyo kala duwan oo hanti ah iyo kala duwanaansho midab. Korodhka xaddiyada zinc ayaa siiya walaxda xoog iyo ductility horumaray. Naxaastu waxay u dhaxayn kartaa midab casaan ilaa jaalle iyadoo ku xiran xaddiga zinc lagu daray daawaha.

Haddii maadada zinc ee naxaasta ku jirta ay u dhaxayso 32% ilaa 39%, waxay kordhin doontaa awoodaha shaqo-kuleelka laakiin shaqaynta qabowgu way xadidnaan doontaa.

Haddii naxaasta ka kooban tahay in ka badan 39% zinc (tusaale - Muntz Birta), waxay yeelan doontaa xoog sare iyo hooseeyo ductility ( heerkulka qolka).

Codsiyada naxaasta

Naxaasta waxaa badanaa loo isticmaalaa ujeedooyinka qurxinta ugu horrayn sababtoo ah waxay u egtahay dahabka. Sidoo kale waa wax caadi ah oo loo isticmaalo in lagu sameeyo qalabka muusikada sababtoo ah shaqeynteeda sare iyo adkeysigeeda.

Bronze

Bronze waa daawaha ka kooban ugu horrayn naxaas ah oo lagu daray waxyaabo kale. Inta badan maaddada lagu daray waa tiin, laakiin arsenic, fosfooraska, aluminium, manganese, iyo silikoon ayaa sidoo kale loo isticmaali karaa in lagu soo saaro sifooyin kala duwan oo ku jira walxaha. Dhammaan maaddooyinkan waxay soo saaraan daawaha aad uga adag naxaasta oo keliya.

Bronze waxaa lagu gartaa midabkiisa dahabiga ah ee caajiska ah. Waxa kale oo aad kala saari kartaa farqiga u dhexeeya naxaasta iyo naxaasta sababtoo ah naxaasku waxay yeelan doonaan siddo jilicsan oogada.

Codsiyada Bronze

Bronze waxaa loo isticmaalaa dhismaha farshaxanada, qalabka muusikada iyo billadaha, iyo codsiyada warshadaha sida bushings iyo biraha, halkaas oo birteeda hoose ee is-jiidhka birta ay tahay faa'iido. Bronze sidoo kale waxay leedahay codsiyada badda sababtoo ah caabbinta daxalka.

Baakad

nagu saabsan

* Jaantuska soo socdaa wuxuu tilmaamayaa is-dhaafsiga ganacsi ee kala duwan. Fadlan door midka aad doorbidayso.

ALAAB IIBKA KULUL

Tayada Marka hore, Badbaadada waa la damaanad qaaday